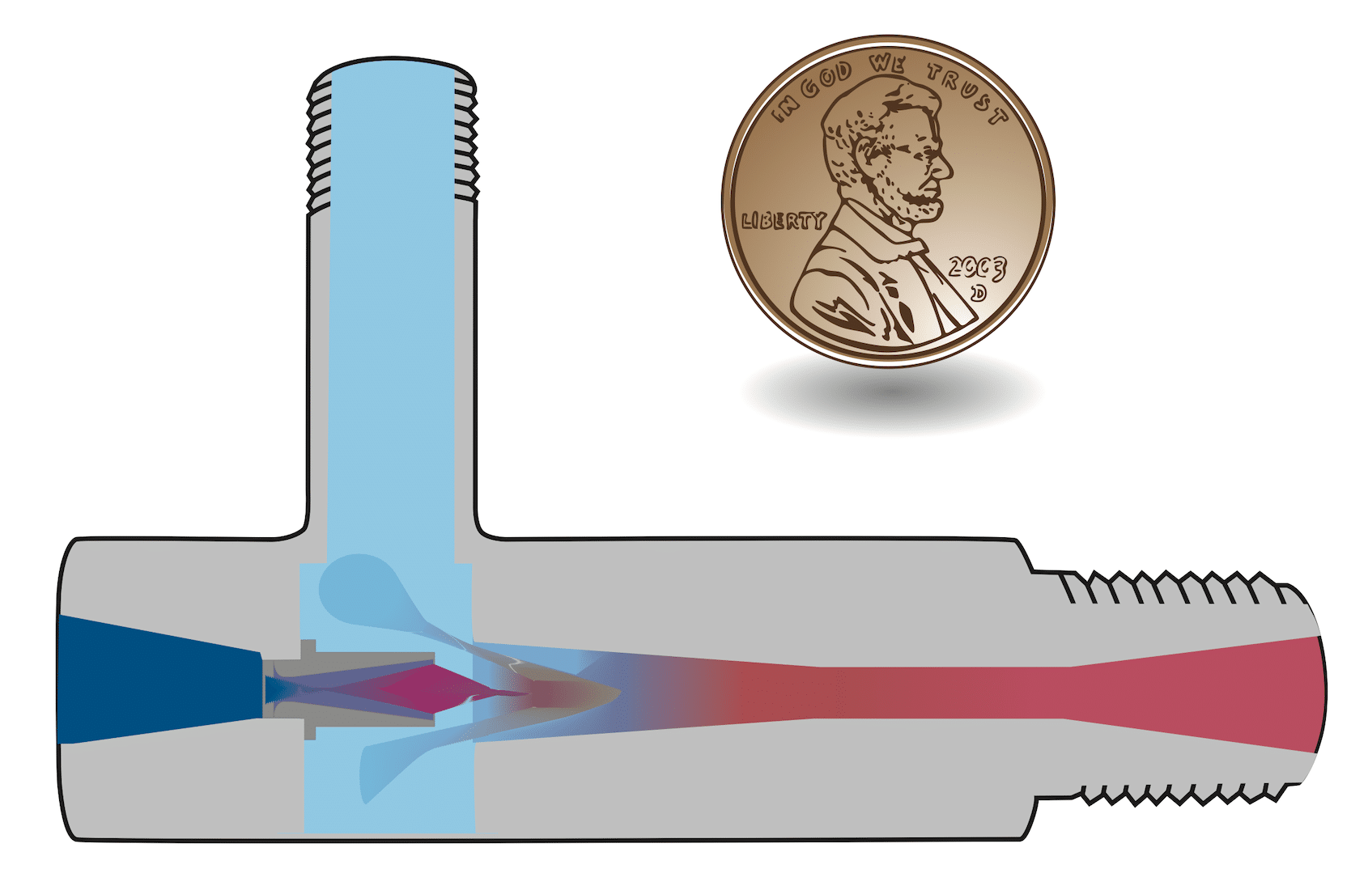

An ejector is a device that can be used to compress or vent gases using another, higher pressure gas as a driving fluid. Ejectors have no moving parts and can operate reliably 24/7 with no oversight and minimal maintenance, even under extreme operating conditions.

Fox Valve has been supplying Air Ejectors, Gas Ejectors, and Steam Ejectors to various industries since the 1960’s and has amassed a wide array of application knowledge ranging from natural gas vapor recovery and methane capture to low-compression tank venting to pump priming to multi-stage vacuum systems designed for deep vacuum below 1 psia / 50 mm Hg.

We would welcome the opportunity to help you with your ejector requirements. Please use the “Request a Quote” button below to submit your application information and one of our experienced engineers will get back to you as soon as possible. If you prefer to call, you can reach us at 973-328-1011 Monday through Friday from 8:30am to 5:00pm Eastern Time.

Our facility in New Jersey stocks a wide variety of air ejectors and ready-to-assemble components, available with or without custom modifications, in sizes from 1/8” to 6” in stainless steel, PVC, and CPVC. We also have a large inventory of other less common materials. Please contact us to review your requirements and see how we can help, or check out the information available here at our website.

Evacuating, exhausting, or venting vapors from vessels, tanks, railcars, or refining processes can be accomplished with simple, no-moving-parts venturi jet ejectors. We offer a wide range of air ejectors driven by either low-pressure blower air or high-pressure compressed air, as well as gas ejectors designed to operate with any gas that you have available.

Typical Applications

- Evacuating pipelines, vessels and tubing of explosive or toxic fumes before maintenance

- Exhausting air at 700° F containing cement kiln dust from cement kilns

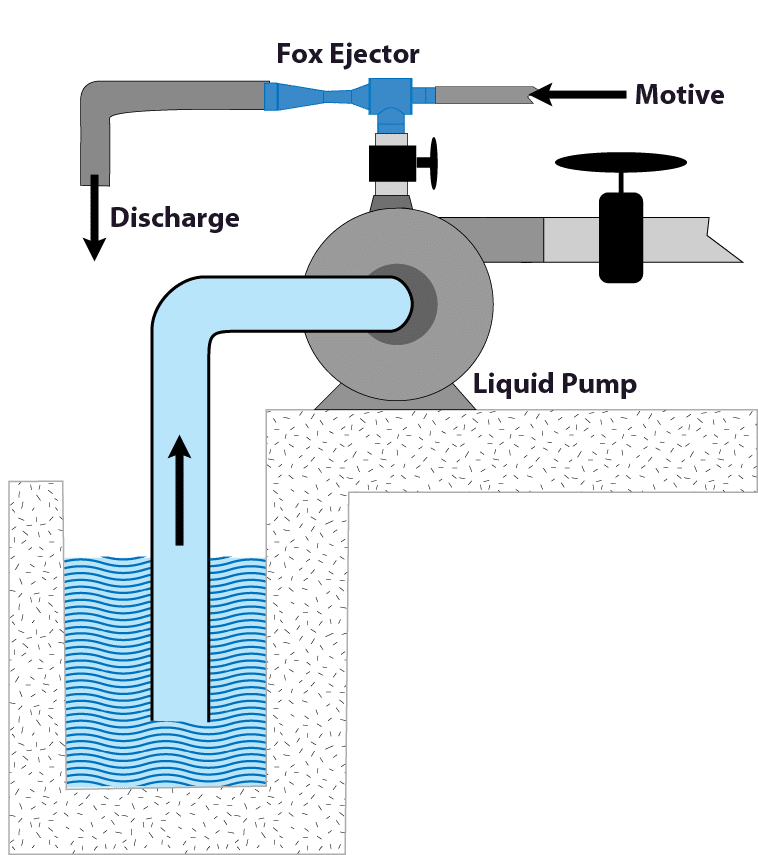

- Air Ejectors are commonly used for Pump Priming

- Creating vacuum in evaporators, crystalizers, deodorizers and other chemical and food processing applications

- Venting methane and sewer gasses from landfills, WTP’s, natural gas processing

- Gas Ejectors are commonly used for blending gasses in precise mixture ratios (Argon + chlorine in a recent application)

- Evacuating Sulfur fumes (H2S) from sulfur pits, trucks and tanks with steam jacketed ejectors, maintaining internal gas temps above 280° F to prevent solidification

- Venting Engine exhaust, fumes, and CO2, etc – including creating deep vacuum on jet and rocket engines for high altitude simulation

- Exhausting explosive or radioactive gasses

- Blowdown: Pass gasses through venturi ejector from a vessel or pipeline at up to 5000 psig during initial purging, then venturi ejector completes evacuation down to 1 to 2 psia

- Blending gasses (optional with Fox sonic choke on suction) to blend to precise mixture ratio

What do we mean by “off-the-shelf” gas ejectors?

Fox maintains a large inventory of assembled and un-assembled 1/4″ to 8″ Fox venturi ejectors in carbon steel and stainless, manufactured in Dover, NJ, USA. This large inventory of un-assembled ejector components enables Fox to quickly make modifications to ejector internals to suit application requirements—and still often ship in 2 days to 2 weeks. This includes re-machining motive nozzle orifice to define required motive gas consumption, welding nozzle in place if required, and welding on flanges or other end connections or adapters—all in our building.

Gas Sampling for Analyzers and Instrumentation with Mini-Eductors

Fox Air-Driven Mini-Eductors have been installed on thousands of analyzer systems for gas sampling since the 1960’s. Please visit the Mini-Eductor section of our website for more information.

Schematics of Typical Applications

Pump Priming with Air Ejectors

Venting Methane and Natural Gas to Flare Header in Oil and Gas Applications

Global environmental organizations have identified methane – the primary constituent of natural gas – as a major contributor to global warming. Oil & gas wells, gas processing plants, and onshore and offshore drilling platforms and sites have been identified as possible sources of methane release via leaks and fugitive emissions. Fox venturi ejectors have been used since the 1980’s to capture released gas and return to process or a flare header or another destination.

For information about Fox Gas Ejectors used in the oil and gas industries, please visit our Natural Gas Ejectors page.

Purging or Evacuating Piplines or Tubing

Creating Deep Vacuum to 1 psia with a Two-Stage Air Ejector

Mechanical Properties of Available Fox Ejectors

- Line Sizes: 1/4 to 42 inch diameter (6mm to ~1m)

- Temps: -350° to 2000° F (to 1090° C)

- Materials:

- Metals: Stainless, Monel, Hastelloy, Titanium, Alloy 20, Aluminum, or Any Machinable Metal

- Plastics: PVC, CPVC, Teflon-Lined, Kynar-Lined

- Off-The-Shelf Carbon Steel or Stainless Gas Ejectors: 1/4″ to 8″

- Off-The-Shelf Plastic/PVC Gas Ejectors: 1/2″ to 3″; CPVC 1/2″ to 2″

- Custom built/Custom engineered Gas Ejectors: 1/4″ to 42″

- MAWP available to 10,000 psig (700 barg)

- End Connections:

- Threads: NPT, BSP, SAE 45° Flare, AN 37° Flare

- Flanges: 150# to 3000# ANSI, DIN Flanges, or any custom-built flange to mate to any equipment

- Tubing: Stub ends of any specified tubing, inch or mm

- Food-Grade: Tri-clamp or other sanitary/hygienic ferrules

- Weld: Butt weld prep ends

- Available Processes: Electropolish, oxygen cleaning, passivation, anodizing, etc.